[vc_row][vc_column][vc_column_text]Our OE quality bearings are engineered to minimize wear and slippage while maximizing reliability.[/vc_column_text][/vc_column][/vc_row]

Mighty hub bearing assemblies, or Generation 3 bearings, combine a sealed wheel bearing with other components to create a complete hub bearing unit. Where applicable, hub bearing assemblies will include electronic sensors for ABS and traction control.

Ball bearings are designed for applications requiring low friction resistance, high speed capabilities, and low maintenance. Ball bearings are primarily designed for use on rear axle applications.

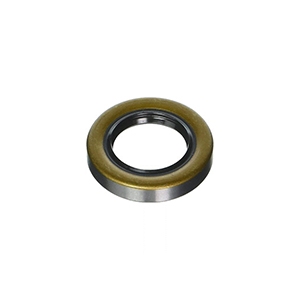

Grease seals perform two important functions in a wheel bearing assembly. They protect the bearing by keeping the lubricant in while blocking contaminants out. Worn seals allow bearing lubricant to leak, increasing bearing wear.

Tapered bearings consist of two components, the bearing and cage assembly, and the bearing race. These bearings install into a separate rotor or drum hub, and ride on a spindle.