The 2013 Ford F150 had been starting perfectly, and without warning, suddenly encountered a no-start symptom. That is the way that batteries often fail. Testing the battery reflected an 8-volt reading. It was four years old and had probably exceeded its life expectancy by approximately one year. A charging system test confirmed there was nothing wrong with the alternator. Replacing the battery restored the engine cranking speed, and all seemed well, but unfortunately, there would be more to this story. A few nights later, the vehicle encountered a slow cranking symptom due to a discharged battery. In the presence of darkness, it was revealed that the instrument cluster lights were remaining illuminated when they should have timed out, and this was likely the reason for the discharged battery.

TELL-TALE SYMPTOMS

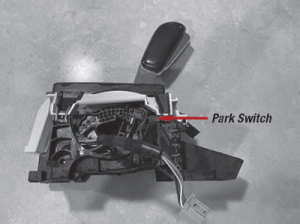

The culprit for the lamp continual illumination was a defective park position switch located in the floor shifter assembly (see illustration). The body control module was waiting on the park position switch signal to time out and would then extinguish the instrument panel lamps. In addition to continuous illuminated instrument panel lamps, a defective park position switch can be confirmed by observing the gear selector in the dash. With the ignition switch in the on position, the park indicator (P) should be illuminated when the gear selector is in the park position. If it is not illuminated, the park position switch is likely defective. The plunger in this small switch takes a constant pounding when the shifter is placed in the park position and the shifter lock is released. This switch is not a replaceable item from Ford, requiring a replacement of the complete shifter assembly in a cost range of approximately $600 for the part, plus labor. Vehicles affected include 2011-2014 F150 trucks. The good news is…the switch is available from the aftermarket.

REPLACING THE PARK SWITCH

The switch can be replaced without removing the shifter from its mounted position. Obviously, the shifter console upper trim panel will have to be removed to gain access to the switch. Purchase a brand name switch, such as a Dorman 905-026. Our first encounter was with a no name brand switch, which resolved the lamp illumination but would not allow the ignition key to be removed from the ignition key lock assembly.

TROUBLESHOOTING ELECTRICAL PROBLEMS

When troubleshooting electrical problems or components, the first check should be the source of energy, and that would be the condition of the battery. Make certain it is fully charged, and the battery cable connections are clean and tight. Minute resistance or voltage variations can have an effect on the system operation. This is especially a problem with electronic control modules that monitor the electrical values of the electronic components to determine if they are operating in their desired range. Often, terminal resistance related conditions that can affect the system or component operation are not measurable with test instruments found in most repair shops. Intermittent or hard failures are often resolved by moving or repositioning a wiring harness, disconnecting and reconnecting a connector, or performing a ground circuit clean-up. These simple checks can often prevent the replacement of some expensive electrical/electronic components. Multiple circuit/component failures are often the result of poor grounds. Check the wiring diagrams to determine if those failed circuits share a common ground.

LOW VOLTAGE AND ELECTRONICS

Major challenges can result with the vehicle’s electronics when a low voltage condition occurs. Low voltage conditions can result when a vehicle is not driven daily, especially vehicles that may be parked for 2-3 weeks. The current drain on the battery is a normal characteristic due to the parasitic current drain necessary to keep certain accessories/devices and memories alive. This electrical drain is usually in the range of 30 ma to a max of 50 ma on vehicles with highly optioned electrical accessories. This amount of electrical drain is not an issue on vehicles driven daily at speeds above 1,000 RPM.

A common mistake is leaving a fob in the vehicle or within 25 feet of the vehicle when parked, as its presence will prevent the computers from entering the sleep mode, resulting in a battery discharge condition. A low voltage condition results in modules not communicating, resulting in some anomalies with the vehicle’s electrical system. Many hours of diagnostic time can be invested searching for a system or component related failure when a low battery condition, poor electrical connection, or voltage drop during cranking was the culprit.

When diagnosing a battery discharge condition, pay special attention to any electrical accessories that may have been added to the vehicle. Add-on devices or electrical accessories can influence other systems or components. Be aware of any electrical device, monitoring or tracking device that may be plugged into the Assembly Line Data Link (ALDL) connector as it can influence the vehicle’s electronics. Troubleshooting symptoms resulting from electrical interference via the ALDL connector can be a challenge, as the accessory is often removed prior to taking the vehicle in for repairs. Question the vehicle owner concerning the use of such accessories, or you may be chasing a problem that has been removed from the vehicle prior to you receiving it for repair.

FACTORY BULLETINS

Consider Ford Bulletin 23-2133…Engine Will Not Turn Off/Various Electrical Symptoms.

Some 2020-2022 Ford Super Duty trucks may encounter a condition where the engine will not turn off or have various electrical symptoms including a dead battery, horn stays on, and a no crank/no start symptom. In addition, there may be an illuminated anti-lock brake system (ABS) indicator with diagnostic trouble codes C0020 and U3003 stored in memory. Ford advises these symptoms may be the result of moisture intrusion into the battery junction box located beneath the hood. The accumulation of moisture may be related to the cover of the battery junction box not being properly sealed due to broken cover tabs or the latching fingers not being properly secured. The service bulletin references a replacement battery junction box and cover.

Before getting too deep in the diagnostics, check for Factory Service Bulletins. The information contained can save a lot of diagnostic time. Some of the solutions offered may not be a diagnostic strategy that you would normally take.

View PDF

Best Car Parts In Ireland – Your update is the best, informative, and helpful.

We’re glad to hear our blogs are helpful – thank you for the feedback!