Customer complaints involving howling, whining, shudder or grinding noises during parking lot maneuvers in Auto Mode or highway speeds in 4HI or Auto may occur on four wheel drive GM trucks and SUV vehicles. Vehicles affected range from 2014–2023 year models. Specific applications can be identified in GM Service Bulletin 19-NA-136.

Some vehicle owners complain that a noise can be heard in 4HI but diminishes when the selector is switched to 2HI. The source of the noise may be coming from the transfer case. GM states that the condition is the result of a normal transfer case break-in and wear resulting in excess contaminants accumulating in the fluid.

Diagnosing transfer case noise:

Perform the following road test to determine if the source of the noise is coming from the transfer case.

If the noise is present when performing the road test, switch the transfer case selector to 2HI. If the noise diminishes, this confirms the source of the noise as coming from the transfer case. GM recommends a transfer case fluid replacement.

Clicking, ticking, grinding or ratcheting noises from the front hubs while operating in the 2WD mode may be due to a mechanical or vacuum related issue. The front hubs on 2006–2020 F150 4X4 (except Raptor) and 2003–2020 Expedition and Navigator 4X4 vehicles are equipped with actuators referred to as Integrated Wheel Ends (IWEs). The actuators function via engine vacuum and spring tension.

Vacuum Operated Hubs…The front hubs are engaged during periods of no vacuum to the actuators. When vacuum is applied to the actuators, the front hubs are disengaged, resulting in the vehicle operating in the 2WD or free-wheeling mode.

Noisy IWEs…The clicking, ticking, grinding or ratcheting noises from the front hubs are usually the result of a partial engagement of an IWE. While the symptoms may be the result of mechanical damage to the IWE, loss of vacuum is usually the culprit. The absence of vacuum locks the hubs in position for 4X4 operation. A partial vacuum loss can result in a partial engagement of the hubs and the gear teeth grinding or shearing. A loss of vacuum on one IWE can result in noise or damage to the opposite IWE. Heavy acceleration resulting in a drop in manifold vacuum can affect the engagement of the hubs.

IWE Components…The IWE components are comprised of the following:

System Checks…When diagnosing noise symptoms, perform some quick checks prior to removing the hub components to determine if mechanical damage has occurred to the teeth on the IWE. With the front end of the vehicle supported safely on jack stands, rotate each tire/wheel while observing the half shaft on each side:

A faulty check valve, solenoid, leaking vacuum reservoir or hose can result in a low vacuum condition. This can result in damage to the IWE teeth, requiring replacement of the components. The solenoid and check valve are common failure items. The solenoid is often damaged due to water intrusion. Its position on the cowl makes it highly susceptible to water entry. Often, the water enters the solenoid and travels through the vacuum hoses contaminating the IWEs, causing corrosion and thereby preventing engagement/disengagement of the hubs.

When driving the vehicle in 2WD, and you suspect partial engagement of one of the IWEs as the source of the noise, place the selector switch to a 4WD position. If this eliminates the noise, partial engagement is the culprit.

With the exception of an electrical check on the vacuum control solenoid, a handheld vacuum pump and vacuum gauge will perform most tests necessary to pinpoint the problem.

The IWEs can be permanently engaged on 2006-2020 F150 (except Raptor) and 2003-2020 Expedition and Navigator vehicles equipped with Torque on Demand Transfer Cases. Ford offers this alternate solution to eliminate the clicking, ticking, grinding or ratcheting noises due to partial IWE engagement by permanently engaging the front hubs.

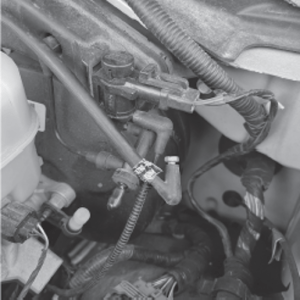

If the Mode Selector Switch includes a 4A selection, the front hubs can be permanently engaged by removing and plugging the vacuum source to the IWEs. Locate the vacuum supply line (see illustration). Disconnect and plug the vacuum source. Ford recommends removing the vacuum hose and plugging both the source vacuum port and check valve with vacuum line caps supplied in their kit number W716372-S300. We accomplished the same, as displayed in the illustration, by disconnecting the vacuum hose from the check valve and plugging the vacuum hose at that end and capping off the check valve port to prevent moisture/dirt from damaging the check valve and solenoid. Either method of removing the vacuum source permanently engages the IWEs without affecting other functions.

If the Mode Selector Switch only includes 2H, 4H and 4L positions (does not include 4A) and the vehicle is a 2017– 2018 F150 then Ford offers a re-program for the Transfer Case Control Module.

The updated calibration changes the IWE operation at start-up. According to Ford, when the ambient temperature is above 32 degrees F the IWEs stay engaged regardless of a 4WD mode selection for approximately 0.5 miles. The IWE engagement only occurs once per key cycle and is not reset when shifting between park and drive. The TCCM uses this strategy to delay vacuum use until vacuum-intensive engine start-up has been completed and sufficient vacuum is available to fully disengage the IWEs.

Leave a Reply